Bentonite Carbon Premix

Product Details:

- Product Type Bentonite

- Density 0.9 Gram per cubic centimeter(g/cm3)

- Strength N.a

- Moisture 12

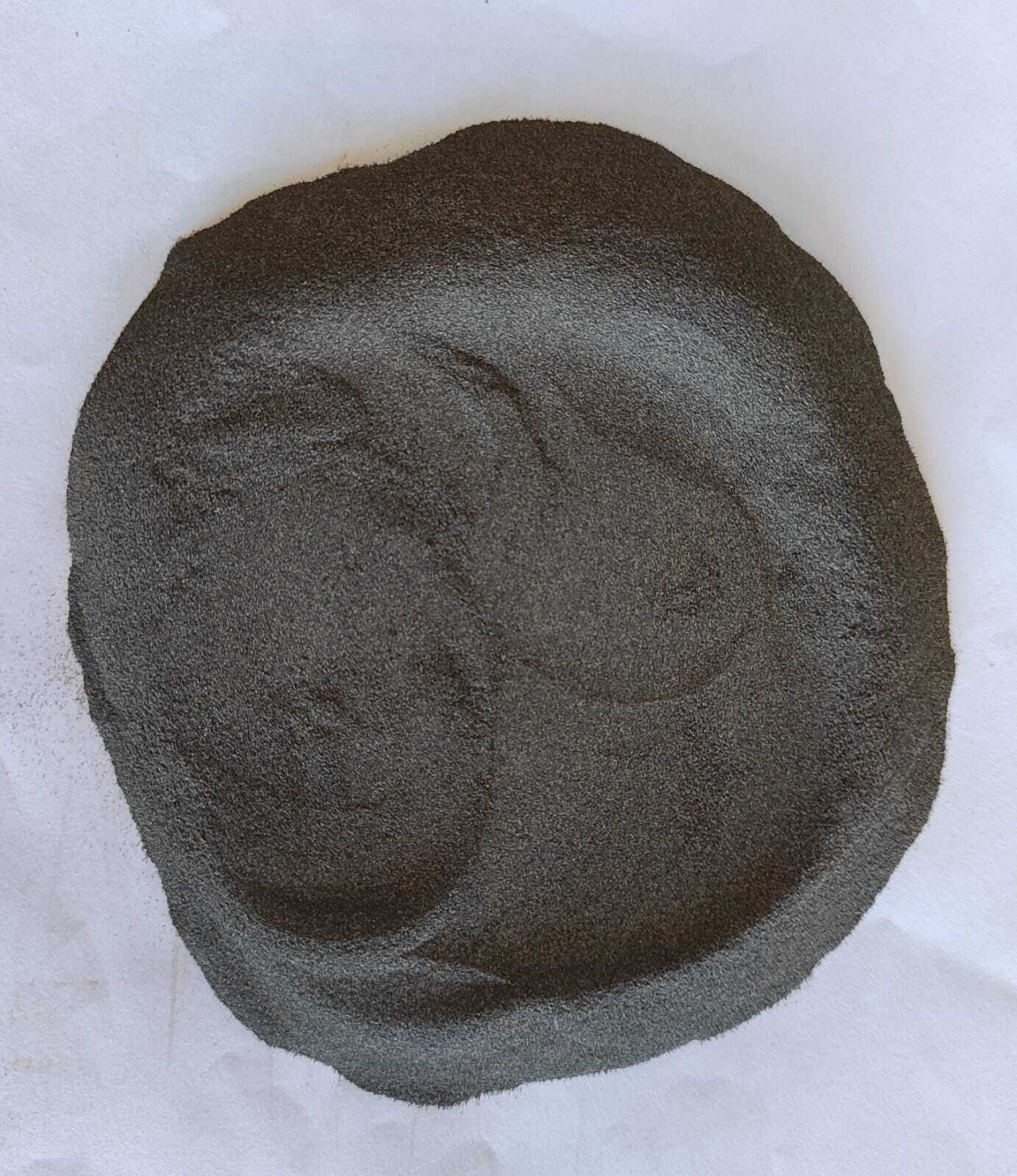

- Appearance Powder

- Application Metallurgy

- Color Grey

- Click to View more

Bentonite Carbon Premix Price And Quantity

- 8000.0 INR/Ton

- 20 Metric Ton

Bentonite Carbon Premix Product Specifications

- Bentonite

- N.a

- Powder

- 0.9 Gram per cubic centimeter(g/cm3)

- Metallurgy

- 12

- Grey

Bentonite Carbon Premix Trade Information

- Mundra

- Telegraphic Transfer (T/T)

- 3000 Metric Ton Per Month

- 5 Days

- Yes

- Free samples are available

- 25kg,50kg,1mt Jumbo bags

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- Iso 9001:2015

Product Description

Selectively Mined Premium Quality Bentonite and lustrous carbon / coal dust are commonly used together in foundry operations as they offer several advantages over other materials when used in combination.

Benefits

Improves the surface finish of the casting, prevent metal penetration, and reduce the likelihood of sand defects.

Minimises casting Defects like Scabbing, Rattail, Blow holes.

New sand addition is reduced and lesser generation of Dead Clay.

Improves the flowability of foundry sands, making it easier to pack and distribute the sand in the mold. This helps to increase productivity and reduce the time needed for finishing and cleaning castings.

When lustrous carbon is used in combination with bentonite, it can help to reduce the amount of binder needed to hold the sand grains together.

Specification

|

Grade |

Foundry |

|

Packaging Size |

50 kg |

|

Packaging Type |

PP Bag |

|

Usage/Application |

Foundry |

|

Form |

Powder |

|

Density |

1.10 % |

|

Shelf Life |

2 Years |

|

Ph Value |

9 |

|

Brand |

Kutch Bento |

Other Products in 'Bentonite ' category

|

KUTCH BENTO CLAY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |